ANSI flange specifications form the backbone of piping system design and safety across countless industries, from oil and gas to water treatment and power generation. The term “ANSI flange” refers to flanges manufactured in accordance with standards overseen by the American National Standards Institute (ANSI), a private, non-profit organization that has been coordinating and approving U.S. standards since 1918. These specifications provide a critical framework for dimensions, pressure-temperature ratings, materials, and tolerances, ensuring that components from different suppliers fit together safely and reliably. This comprehensive guide will delve into the details of the governing standards, helping engineers, designers, and procurement specialists make informed decisions for their piping systems.

It is crucial to clarify a common point of confusion: while often called “ANSI flanges,” the detailed technical standards are actually developed by the American Society of Mechanical Engineers (ASME) . ANSI’s role is to accredit the standards, such as ASME B16.5 and ASME B16.47, ensuring their consistency and national recognition . Therefore, when you encounter “ANSI B16.5,” it is a reference to the ASME B16.5 standard that has been approved by ANSI.

Table of Contents

The Governing Standards: ASME B16.5 and ASME B16.47

The world of ANSI flanges is primarily governed by two key ASME standards, which are differentiated by size range.

ASME B16.5

This is the primary standard covering Pipe Flanges and Flanged Fittings for sizes from NPS 1/2 through NPS 24. It includes pressure class designations of 150, 300, 400, 600, 900, 1500, and 2500 . This standard provides comprehensive data on dimensions, tolerances, materials, marking, and testing for all common flange types.

ASME B16.47

For larger diameter piping systems, the ASME B16.47 standard takes over, covering flanges in sizes from NPS 26 through NPS 60. This standard is further divided into two series: Series A (which is more robust and incorporates former MSS SP-44 flanges) and Series B (which incorporates API 605 flanges).

Understanding Pressure Class Ratings

A fundamental aspect of ANSI flange specifications is the pressure class rating, often denoted as Class 150, 300, 600, etc. A critical and widespread misconception is that “Class 150” means a flange is rated for 150 PSI at all temperatures. This is not correct.

The class designation is a dimensionless number that represents the pressure rating of the flange at a reference temperature . The maximum allowable pressure for a given flange decreases as the service temperature increases. For example, a Class 150 carbon steel flange may be rated for 150 PSI at 100°F, but its pressure capacity will be significantly lower at 500°F.

Table: Pressure-Temperature Ratings for ASTM Group 1.2 Materials (Sample Values in PSI).

| Temperature (°F) | Class 150 | Class 300 | Class 600 |

|---|---|---|---|

| 100 | 285 | 740 | 1480 |

| 200 | 240 | 675 | 1350 |

| 300 | 195 | 585 | 1170 |

| 400 | 150 | 475 | 950 |

| 500 | 105 | 335 | 670 |

Key Dimensions and Tolerances

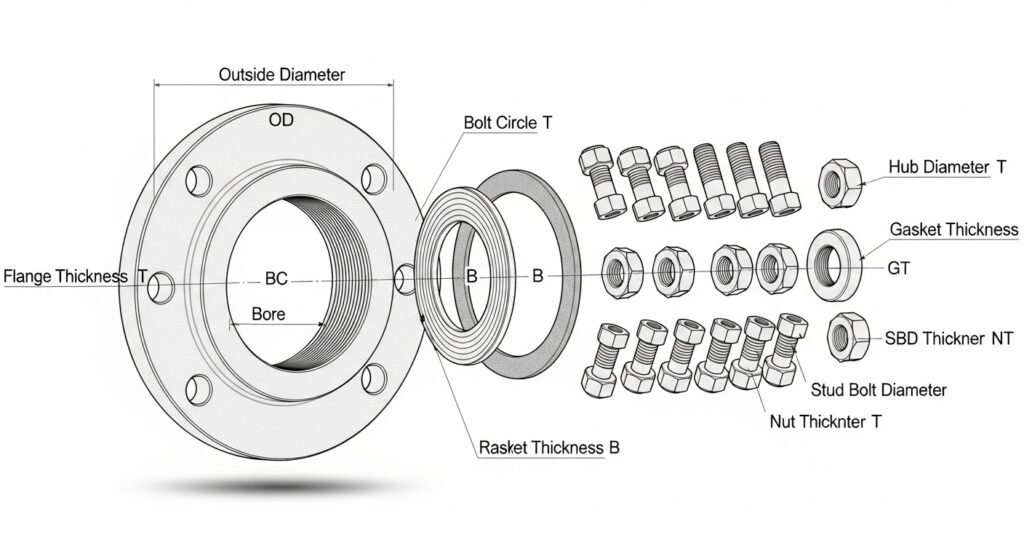

Standardized dimensions are the key to the interchangeability and safety of ANSI flanges. The standards specify precise measurements to ensure compatibility between components from different manufacturers . The most critical dimensions include :

- Outside Diameter (O.D.): The measurement across the outside edge of the flange.

- Inner Diameter (I.D.) or Bore: The measurement of the central opening, which must match the connecting pipe’s flow path to prevent turbulence and pressure drops.

- Bolt Circle Diameter: The diameter of the circle that passes through the center of all bolt holes. This is crucial for proper alignment with a mating flange.

- Bolt Hole Spacing: The number, diameter, and spacing of bolt holes, which are essential for the uniform distribution of bolt load to create a tight, leak-free seal.

Table: Sample ASME B16.5 Flange Dimensions (Class 150, Inches)

| Nominal Pipe Size (NPS) | Flange O.D. (O) | Flange Thickness (T) | # of Bolts | Bolt Hole Diameter | Bolt Circle Diameter |

|---|---|---|---|---|---|

| 2 | 6.00 | 0.69 | 4 | 0.75 | 4.75 |

| 4 | 9.00 | 0.88 | 8 | 0.75 | 7.50 |

| 6 | 11.00 | 0.94 | 8 | 0.88 | 9.50 |

| 8 | 13.50 | 1.06 | 8 | 0.88 | 11.75 |

| 12 | 19.00 | 1.19 | 12 | 1.00 | 17.00 |

Common ANSI Flange Types and Their Applications

The ANSI standards cover a variety of flange types, each designed for a specific purpose and offering different advantages.

- Weld Neck (WN): Features a long tapered hub that is butt-welded to the pipe. Ideal for high-stress applications, high temperatures, and cyclic loading due to its excellent structural integrity.

- Slip-On (SO): Slides over the pipe and is secured with two fillet welds. Easier to align than weld neck flanges and lower in cost, making them suitable for low-pressure applications.

- Blind (BL): A solid disk used to blank off the end of a piping system or valve, allowing for future expansion or easy inspection access.

- Socket Weld (SW): The pipe is inserted into a socket in the flange and fillet welded around the hub. Provides good flow characteristics and is stronger than slip-on flanges, ideal for small-diameter, high-pressure piping.

- Threaded (THD): Features internal threads that screw onto a male-threaded pipe. Used in applications where welding is not desirable or permissible.

- Lap Joint (LJ): Used with a stub end that is welded to the pipe. The flange itself rotates freely, making it excellent for systems requiring frequent disassembly or for aligning bolt holes easily.

Material Specifications and Selection

ANSI/ASME standards specify acceptable material grades to ensure flanges can withstand the mechanical stresses and chemical environments of their intended service. The choice of material impacts the flange’s pressure-temperature rating, corrosion resistance, and cost.

- Carbon Steel: ASTM A105 is a common specification for forged carbon steel flanges used in ambient and higher-temperature service.

- Stainless Steel: ASTM A182 covers forged stainless steel flanges (e.g., grades F304, F316) for corrosive environments and high-temperature service.

- Low-Temperature Carbon Steel: ASTM A350 for applications where notch toughness is important at low temperatures.

- Alloy Steel: Grades like ASTM A182 F11, F22, are used for high-temperature service in power generation and refineries.

How to Select the Right ANSI Flange

Choosing the correct flange involves a systematic evaluation of your system’s requirements. For a deeper dive into a common flange type, refer to our dedicated guide on ANSI B16.5 CLASS 150 FLANGES.

- Determine Operating Conditions: Identify the maximum internal pressure and temperature your system will encounter, and consult the pressure-temperature rating tables for your chosen material.

- Identify Pipe Size: Know the Nominal Pipe Size (NPS) of your piping.

- Select Flange Type: Choose a type based on application needs: Weld Neck for high stress, Slip-On for cost and ease, Blind for isolation, etc.

- Choose Material: Select a material compatible with the fluid service and operating environment to ensure corrosion resistance and mechanical strength.

- Specify Facing: The most common is a Raised Face (RF), which improves gasket compression. Flat Face (FF) is typically used with cast iron flanges.

Frequently Asked Questions (FAQs)

1. What is the difference between ANSI and ASME flanges?

“ANSI flange” is a common industry term, but the technical standards are developed by ASME. ANSI accredits standards like ASME B16.5, making them American National Standards. The flanges themselves are interchangeable, and both terms refer to the same products.

2. What does “Class 150” actually mean?

Class 150 is a pressure class designation, not a direct PSI rating. It indicates the flange’s pressure-containing capacity at a reference temperature. The maximum allowable pressure decreases as the operating temperature increases.

3. Can I connect an ANSI flange to a DIN or JIS flange?

While possible, it is not straightforward. ANSI, DIN (European), and JIS (Japanese) flanges have different dimensions, bolt patterns, and pressure ratings. Connection typically requires a special adapter flange or careful engineering to address the mismatches.

4. Where can I find the complete dimensional data for an ANSI flange?

The complete and authoritative source is the ASME B16.5 standard document itself. However, reputable flange manufacturers and distributors often publish detailed dimension charts on their websites based on this standard.

5. What is the scope of the ASME B16.5 standard?

ASME B16.5 covers pipe flanges and flanged fittings from NPS 1/2 to NPS 24, in pressure classes from 150 to 2500. Flanges larger than NPS 24 are covered under the ASME B16.47 standard.

6. Why is bolt-hole spacing important?

Proper bolt-hole spacing ensures the bolt load is distributed evenly around the gasket. This uniform pressure is essential for creating a leak-proof seal and preventing localized stresses that could lead to flange failure.

7. What industries commonly use ANSI flanges?

ANSI flanges are critical components in oil and gas, chemical processing, power generation (including nuclear), water and wastewater treatment, food and beverage processing, and HVAC systems.

Conclusion

Understanding ANSI flange specifications is not merely an academic exercise—it is a practical necessity for designing, maintaining, and operating safe, efficient, and reliable piping systems. By mastering the relationships between standards like ASME B16.5 and B16.47, pressure-temperature ratings, dimensional requirements, and material selection, engineers and technicians can ensure compliance, safety, and performance. Always consult the latest edition of the relevant ASME standards for critical applications and partner with qualified suppliers to source flanges that meet these rigorous specifications.

For all your Puddle Flange requirements, consult with reputable manufacturers and suppliers like Texas Flange, who can provide the right flange solutions tailored to your application’s demands.